Application

YAMASA DX type tools are used for the aim of burnishing the cylindrical holes that have an open and closed end. The tools provide as well as surface hardness and calibration (measurement accuracy) beside of burnishing. Because of the high processing power and speed ability it provides time saving. These are the preference causes for the serial production.

DX There are three types of YAMASA DX burnishing tools according to the process type :

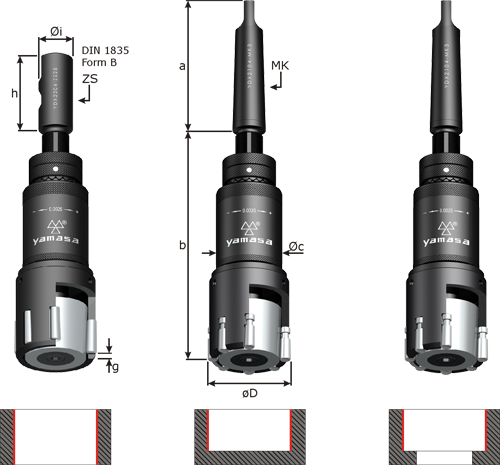

1 ) Through Hole self-feeding

These burnishing tools process the holes that have an open end. The tools provide own feeding speed which is needed while it is processing the workpiece. Feeding occurs free from the machine.

2 ) Through Hole machine-feeding

These burnishing tools process the holes that have an open end. While the tools process the workpiece, the machine provides feeding speed which is needed.

3 ) Blind Hole machine-feeding

These burnishing tools process stepped or fully closed holes up to end. While the tools process the workpiece, the machine provides feeding speed which is needed.

The tool or the workpiece can be turned with the speed of max. 250 m/min. The machine feeding speed is possible from 0,05 mm/rev. to 0,3 mm/rev. for per roller.

Through hole Blind hole Semi blind hole

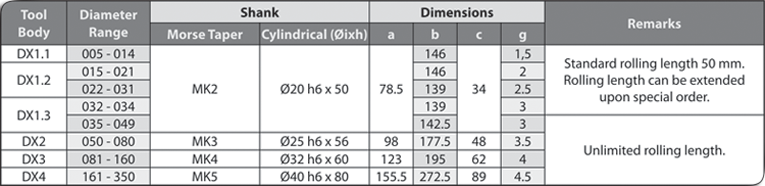

All Dimensions in mm.

Technical Features

The tools are adjusted. The adjustment capacity is changing according to the diameter and types between 0,25 mm and 1 mm. The tools have an adjustment mechanism which gives the possibility to adjust very high precision measurements. For Ø5 - Ø80 mm tools, adjustment precision is 0,0025 mm and for bigger than Ø80 mm tools, adjustment precision is 0,0050 mm. YAMASA DX type roller burnishing tools can process the cylindrical holes up to H8 tolerance with a single adjustment. These tools are capable to process all kinds of metallic materials with 1400 N/mm2 tensile strength and hardness up to max. 42-45 HRC. Tools work by turning to right. Either tool or workpiece may turn. These tools can be used on universal or CNC lathes, machining centers, drilling machines, milling machines or other machines which process by turning. The tools can be fixed to all machines easily and practically. Tools have rather a long life. It is possible to use the tools for a long time without size change due to abrasion.

Tool Structure

YAMASA DX burnishing tools consist of a body and a roller head. The tool body has a precision adjustment mechanism. Cage, cone and rollers are the parts of the roller head. The roller heads fitting in to the same body can be changed. The tool shank may be morse taper or cylindrical. The tools, which are bigger than Ø34 have an unlimited rolling length, for the tools which are smaller than Ø35 exist standard rolling lengths (see table below). For special orders, tools with longer rolling lengths can be produced.