Application

YAMASA CEOS Combined Tools are used to finish the inner surfaces of hydraulic-pneumatic cylinders and tubes. Tools completes skiving and burnishing operation in one pass. Since it is possible to produce quickly and economically high-quality tubes, this technology is preferred to honning methode in serial production.

Roller burnished surfaces provide much more lower surface roughness according to the honned surfaces, in this case too low abrasion value occurs. Therefore, joints running through the cylinder are less worn and has long life. Also the optimal surface roughness is obtained too which is required for sealing. With this technology, tubes which have high surface quality, hardness and worn durability are produced, process time and costs are extremely decreased.

Operation

CEOS generally used on deep hole drilling and skive-burnishing machines. The tools fixed on boring bar of the machine. To realize the operation the tool or workpiece or both of them can be rotated. The skiving head in front is skived the excess material till ajdusted diameter and prepares the optimal surface for the roller burnishing process. The roller head in the back achieve roller burnishig process and smooth the surface roughness and provides last finish size. Knives and roller head will closed automatically, the tool is retracted quickly and the operation is completed without damaging the surface.

Technical Features

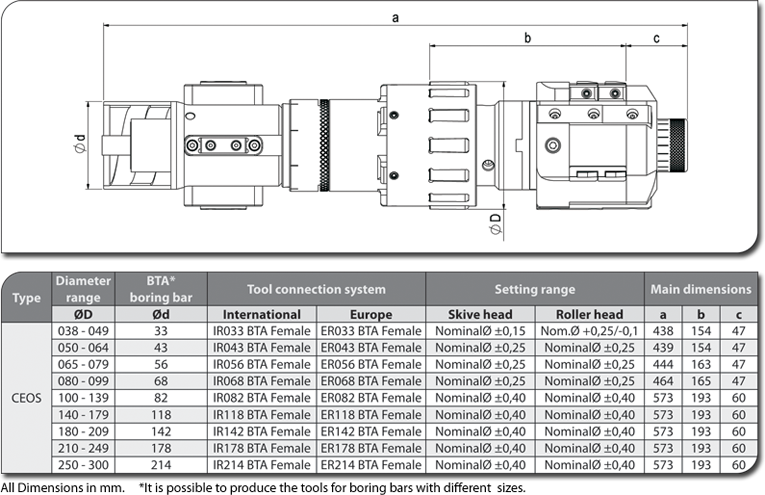

CEOS Type Combined Skive-Burnishing Tools simultaneously skive and burnish the cold drawn and hot rolled tubes. The tools are produced between Ø38-400 mm and as standard with 2 and 3 skiving knives. Cutting depth is possible up to 3 mm in diameter.

The diameter of tools is adjustable, adjust capacity is changing between 0.3-0.8 mm. Skiving head and roller head is adjusted independently from eachother, adjustment mechanism is very precisely, and allows setting to be made in 0.01 mm increments.

CEOS Type Combined Skive-Burnishing Tools, can produced finished tubes with the help of high precisely knife system which can machine rough finish process in one adjustment and one pass till H7 tolerances. Improved integrated roller head harden the inner surface of the tube and burnish it in Ra <0,1 um roughness like a mirror.

Both side Retrac System is available on tools. After retract any scratching problem never occurs. There is systems on CEOS Type Combined Skive-Burnishing Tools which eliminates misalignments , axis failures and wobbling. It is possible to produce with these tools 0,4 - 20 meter long tubes. The tools has long using life, and it is possible to use the tools for a long time without size change due to abrasion.

Tool Connection and Hydraulics Control

BTA Connection System is available on tools. The tool is connected and disconnected only one movement on the boring bar. There are two types of control systems available on the tools that meets the requirements in the market.

1-) International system:

- Aktivation cylinder is integrated on the tool.

- Tool can be controlled in hydraulics and pneumatics or both System.

- System works with 40-100 hydraulic bar pressure.

2-) Europe system:

- Aktivation cylinder is integrated on boring bar.

- Control is done from boring bar.

- System works with approx. 20 bar pressure.