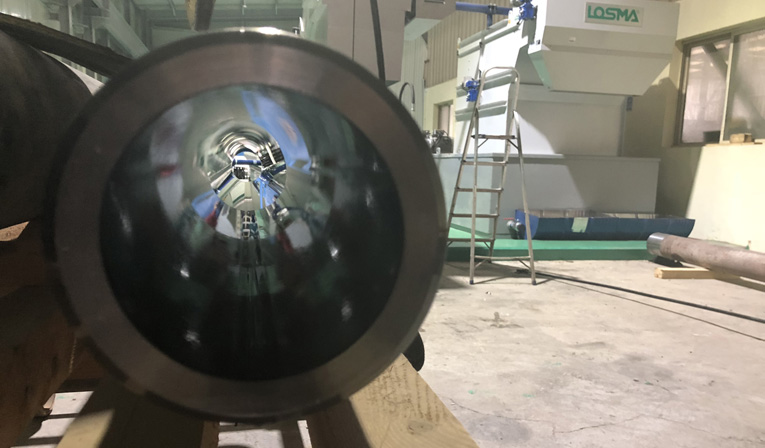

YAMASA Skive-Roller Burnishing Technology provides to you many advantages;

You will save from wear parts!

- Long life wear parts will decrease your consumption drastically!

- The Money you spend for wear parts decrease drastically!

- Replacements are easy, anyone can do it, no need any professionalism.

You will save time!

- Diameter adjustment with indicator provide time saving and convenience..

- High Cutting performance minimize the machining time.

- The replacement of spare parts with longer periods shorten the machine down time.

- Minimized replacement duration privides time savings.

You will produce high quality tubes in every conditions!!!

- It will produce quality tubes by eliminating rippling and axis alignment errors which source from machine.

- Exellent surface quality in one pass (Rz < 1 µm / Ra < 0,1 µm).

- Provides improved cylindrical forms by reducing the circularity till 0,01 mm.

- Reduce rippling or remove completelly.

- It can produce the tubes in large irregularities in one operation.

- High cutting depth offers a possibility of machining hot rolled tubes in one pass .

Your production cost wil be decrease drastically!

- When YAMASA CEO new generation Combined Skive-Burnishing Tools are began to used wear part needs and cost reduction immediately are noticed.

- Decrease in machine downtime and operation, increase in production amount affect production costs positively.

Bu sayfaya girebilmeniz için 18 yaşından büyük olmanız gerekmektedir.

18 yaşından büyük müsünüz?

You have to be over 18 to enter this page.

Are you over 18?